Precision CNC Machining Services

for Custom Metal Parts

ISO-certified CNC milling and turning manufacturer serving Europe and North America. We specialize in custom, non-standard parts with tight tolerances up to ±0.01mm.

Get a QuoteWhat We Can Machine

CNCTAL provides precision CNC machining services for custom metal and plastic parts. From prototypes to small batch production, our capabilities cover a wide range of industries and applications.

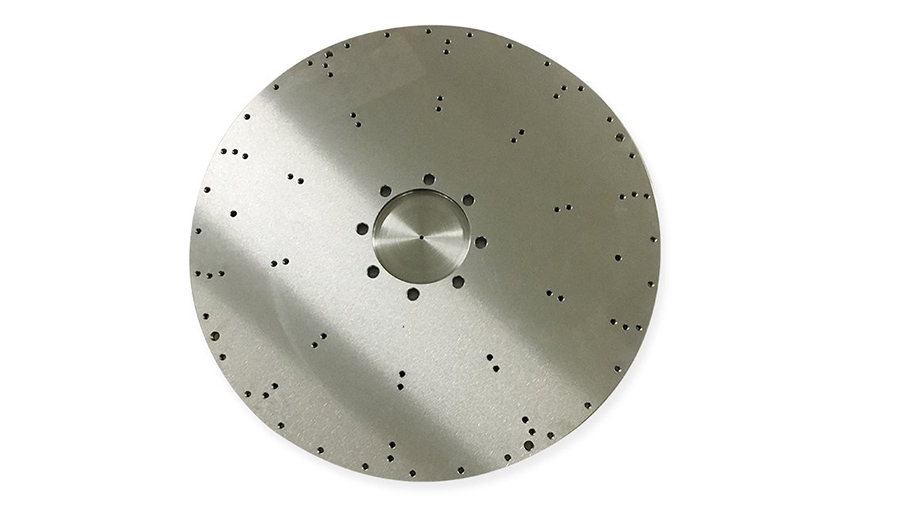

CNC Milling

High-precision CNC milling for complex geometries and tight tolerances. Suitable for aluminum, stainless steel, brass, and engineering plastics.

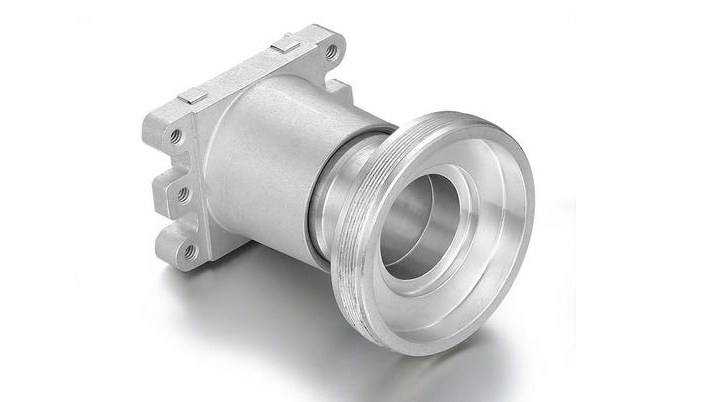

Learn More →CNC Turning

CNC turning services for round, cylindrical, and high-accuracy components. Ideal for shafts, bushings, connectors, and threaded parts.

Learn More →5-Axis Machining

Advanced 5-axis CNC machining for complex parts requiring multi-angle precision and reduced setup time.

Learn More →Custom & Non-Standard Parts

We specialize in custom, non-standard CNC parts based on your drawings, specifications, and functional requirements.

Learn More →How to Get Started

Starting your CNC project with CNCTAL is simple. Just follow these four easy steps:

Send Your Drawing

Share your 2D/3D drawings, specifications, and material requirements.

Receive Quotation

We review your project and provide a detailed quote including cost and lead time.

Confirm Order

Approve the quotation and production plan. NDA & confidentiality guaranteed.

Production & Delivery

We manufacture your parts with precision and deliver them on time.

Materials We Work With

We machine a wide range of metals and engineering plastics to meet different performance, strength, and application requirements.

Aluminum Alloys

Lightweight, stable, and highly machinable. Aluminum is ideal for precision parts requiring tight tolerances and excellent surface finishes.

- Excellent machinability

- Low deformation risk

- Ideal for anodizing

Stainless Steel

Known for corrosion resistance and mechanical strength, stainless steel is widely used in demanding industrial and medical applications.

- Excellent corrosion resistance

- High structural strength

- Consistent dimensional stability

Carbon & Alloy Steel

A balanced choice offering strength, durability, and cost efficiency, especially suitable for mechanical and load-bearing components.

- Good strength-to-cost ratio

- Suitable for heat treatment

- Stable for batch production

Titanium Alloys

Titanium offers exceptional strength-to-weight ratio and corrosion resistance, making it ideal for aerospace and medical components.

- High strength-to-weight ratio

- Excellent corrosion resistance

- Advanced CNC process control required

Copper & Brass

Ideal for electrical and thermal applications where conductivity and precision are critical.

- Excellent electrical conductivity

- Good surface finish

- Precision control required

Engineering Plastics

Engineering plastics provide chemical resistance, low weight, and dimensional stability for non-metal applications.

- Low weight & chemical resistance

- Stable for precision machining

- Ideal for insulation components

Industries We Serve

CNCTAL supports a wide range of industries with precision CNC machined parts, meeting strict quality, tolerance, and performance requirements.

Aerospace

High-precision components for structural, mounting, and functional aerospace applications, with strict tolerance and quality control.

View Industry →Medical

CNC machined parts for medical devices and equipment, focusing on accuracy, surface finish, and material consistency.

View Industry →Automotive

Precision CNC parts for automotive systems, prototypes, and performance components, supporting both development and production stages.

View Industry →Industrial Equipment

Durable and precise CNC components for industrial machinery, automation systems, and heavy-duty applications.

View Industry →Electronics

CNC machined enclosures, heat sinks, and precision parts for electronic devices and components.

View Industry →Robotics

Custom CNC parts for robotic systems, including frames, joints, and high-precision motion components.

View Industry →Quality & Inspection

Quality is built into every stage of our CNC machining process. From raw material inspection to final dimensional verification, we ensure each part meets your drawings and specifications.

- ISO 9001 quality management system

- CMM inspection for critical dimensions

- Incoming, in-process, and final inspection

- Tight tolerances up to ±0.01mm

- Full inspection reports available upon request

Why Choose CNCTAL

We are not just a CNC machining supplier — we are a long-term manufacturing partner focused on quality, reliability, and clear communication.

Direct Manufacturer

In-house CNC machining with no middlemen. Better cost control, faster response, and consistent quality.

Engineering Support

Our engineers review drawings and provide manufacturability feedback to reduce risk and cost before production.

Flexible MOQ

From prototypes to small batch production, we support flexible quantities without compromising precision.

Stable Global Delivery

Experienced in EU & US export with reliable packaging, documentation, and on-time shipment.

What Our Customers Say

CNCTAL has delivered precision CNC parts to clients worldwide. Here’s what they say about working with us:

Trusted by Leading Companies Worldwide